K-Zeitung: Polyketone for robust weld lines

Weld lines are considered a critical component in thermal management and flame-retardant materials in electric cars. Polyketones offer a solution.

Thermal management is crucial for the optimal performance of electric vehicles (EVs). In cars with combustion engines, PPS, PPA or hydrolysis-resistant PA66 are used in this area. The challenge here lies in the weld lines, which are exposed to chemical attack under continuous pressure from the coolant. This is where PP comes into play, an economically attractive alternative with excellent weld line stability in water glycol at different temperatures.

However, the Achilles heel of PP in electric cars is its long service life. In contrast to combustion engines with a typical service life of 3,000 to 5,000 hours, electric car systems require a service life of up to 30,000 hours, and new concepts for self-driving cars are even aiming for 45,000 hours. Many PP weld lines do not last that long, PP tends to creep.

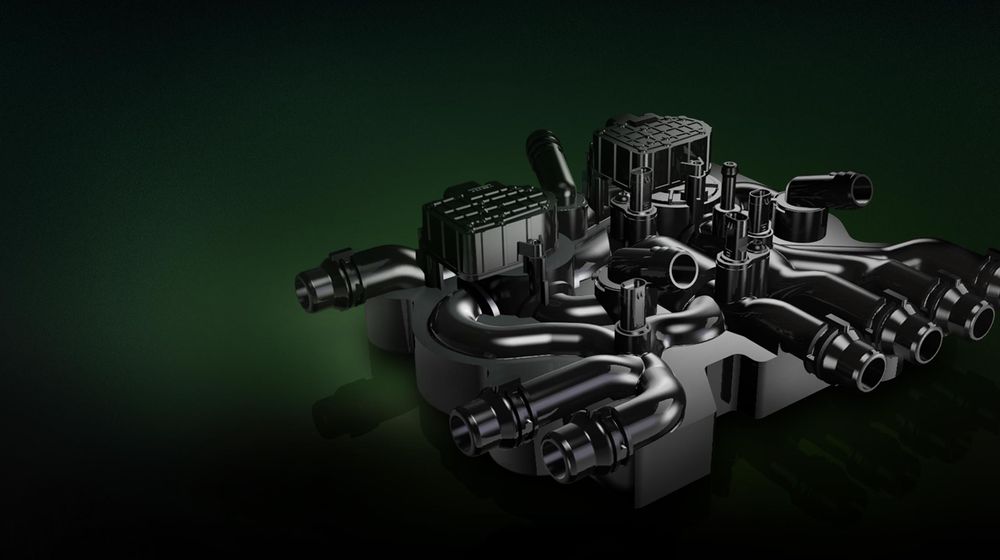

This is where Akrotek PK, a polyketone (PK) from Akro-Plastic, comes into play. With the introduction of black, laser-transparent (VM GF 30 LT black) and laser-absorbent (VM GF 30 black) variants for laser welding, coupled with a new stabilizer package, thermal management in electric cars can be made more cost-effective, reliable and efficient. "Our new polyketone compound extends the process window and ensures reliability even with laser-transparent black variants," says the manufacturer Akro-Plastic. According to Akro-Plastic, Akrotek PK enables OEMs to develop applications with long-term stability at a very good price-performance ratio.

Image dimensions not found

Change image or reupload it

Polyketone for busbars

Polyketone can also demonstrate its advantages in flame-retardant applications in electric cars - for example in busbars. Flame-retardant PBT grades often exhibit weak weld line strength. This is why many rely on PA6 and PA 6.6. However, their performance decreases significantly at higher temperatures of 80-100 °C, which makes them unsuitable for applications that require permanent insulating behavior, especially in environments with higher voltages.

This is where Akro-Plastic's polyketone Akrotek PK-VM GF 30 FR comes into play, available in both black (8604) and orange (8537) versions. Both grades are UL94 RTI listed and offer all the properties required for flame-retardant applications such as busbars in electric cars, including robust weld line strength.

Disclaimer: All specifications and information given on this website are based on our current knowledge and experience. A legally binding promise of certain characteristics or suitability for a concrete individual case cannot be derived from this information. The information supplied here is not intended to release processors and users from the responsibility of carrying out their own tests and inspections in each concrete individual case. AKRO®, AKROMID®, AKROLEN®, AKROLOY®, AKROTEK®, ICX® and PRECITE® are registered trademarks of the Feddersen Group.