Image dimensions not found

Change image or reupload it

Weight Savings through Hybrid Components

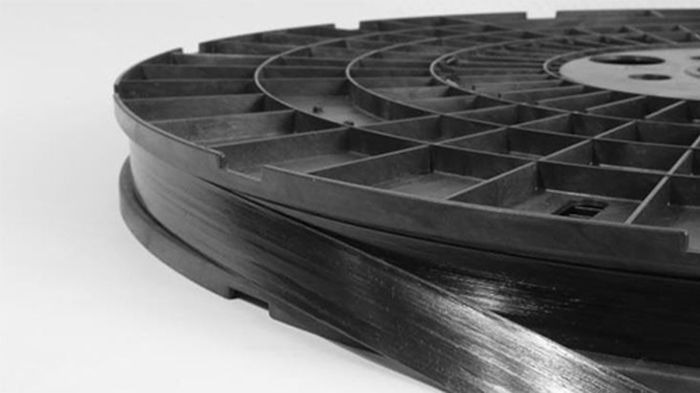

The electric motor is a central part of the powertrain in electric vehicles. As part of the "fabulous" project, the electric motor is being made more efficient and lighter by replacing existing metal components with newly developed hybrid components made of metal and plastic. This is necessary because the wheel hub motor significantly increases the weight of the wheels and thus impairs driving dynamics, ride comfort and efficiency. The focus in material development is on novel partially aromatic and aliphatic polyamides, which are processed into carbon fiber-reinforced UD tapes.

Innovative high-performance composites

Matrix Material requirement

The task of AKRO-PLASTIC GmbH is the development of materials based on partly aromatic polyamides, so-called polyphthalamides (PPA), both for the production of UD tapes and for the use in injection molding. For the application, consistent properties up to an operating temperature of 120°C are crucial, and very good chemical resistance to oils and other media occurring in the electric motor is required.

The impregnation behavior of the PPA, i.e. the wetting of the carbon fibers with the polymer during the production of the UD tapes, and the filling behavior during processing in the injection molding or back-pressing process will contribute significantly to the success of the project.

Image dimensions not found

Change image or reupload it

Operational Strength and Corrosion Resistance of different Materials

The use of PPA tapes with continuous carbon fibers involves the risk of corrosion in the event of contact between fibers and metal inserts. Therefore, tapes with very polymer-rich edge layers are being developed. These edge layers are intended to prevent direct contact between carbon fiber and metal and improve the adhesion of the laminate structure with the metal components.

Consideration of the Complete Value Chain

The "fabulous" project covers the entire value chain from high-performance material development, tape manufacturing and tape laying processes, to component development with the aid of computer-aided simulation of toolmaking, component manufacture by injection molding/back compression molding and quality assurance, right through to the finished electric motor.

The processes of tape laying, surface functionalization of inserts and the tool-based forming process for joining multiple dissimilar materials are developed. The multi-material engine component is designed to be material-appropriate and operationally stable for the expected loading temperatures and optimized for near-zero elongation.

Function-integrated powertrain components for electromobility made possible by innovative high-performance composite materials

Image dimensions not found

Change image or reupload it

Support Measure

The project is funded under the funding measure "From Material to Innovation" in accordance with Article 25 of Regulation (EU) No. 65112014 of the European Commission of 17.06.2014. The project duration is designed for three years for the period from 01.06.2019 to 31.05.2022.

Das Förderkennzeichen dieses Forschungsprojekts lautet: 03XP0214C

AKRO-PLASTIC GmbH

CirComp GmbH

FEV Europe GmbH

FKT Formenbau und Kunststofftechnik GmbH

Fraunhofer IPT

Fraunhofer LBF

Gubesch Thermoforming GmbH

M.TEC

SURAGUS GmbH