PRECITE® PBT

PRECITE® E

PRECITE® E is our brand for polyethylene-terephthalate compounds. PET-Compounds have higher stiffness and strength than PBT-Compounds with same reinforcement level. PET can be used at elevated temperature and has an excellent surface, even at high temperature.

PRECITE® E – our PET based compounds are the right choice if high stiffness and strength is required at elevated temperature. PET offers a 20% higher stiffnes than PBT compounds with same fiber content. The excellent surface, even in high reinforced compounds can be also helpful for tribological applications. As PET is a polyester, it offers excellent dimensional stability due no water uptake.

In opposite to most PBT compounds PRECITE® E can also be used for stiff applications in automotive interior like for instance air vents. It reaches good surface quality and complies with requirements of emissions and odor.

High reinforced for metal replacement

High surface quality

Good wear resistance

Elevated temperature vs. PBT

Image dimensions not found

Change image or reupload it

Compared to other polymers such as PA 66, PA 6 and also PPA, PET Precite E also shows high dimensional stability under moisture. Components can thus be used precisely and independently of environmental influences. The stress-strain curve shows various compounds with 50% glass fiber reinforcement. Compared to standard polyamides, which clearly lose mechanical properties after water absorption, whereas PRECITE® E GF 50 natural (7300) does not change mechanically or dimensionally. Especially at 80°C, the strength of PET becomes apparent, as can be seen here in comparison with PA 6 PA 6.6 and PPA. In addition, PET has a better CO2 footprint than standard polyamides.

Image dimensions not found

Change image or reupload it

In addition to high stiffness at high elongation, these compounds exhibit strong bonding between matrix and carbon fiber. Even at 80 and 120 °C, PRECITE® E - ICF 30 black (7429) still shows good mechanical properties and is therefore already established in various applications for structural components (also in interiors): Also worth mentioning is the good surface finish, even at high reinforcement levels, which recommends the material for components with high aesthetic requirements (ventilation louvers or windshield wiper arms), components for kitchen use or tools in the construction industry.

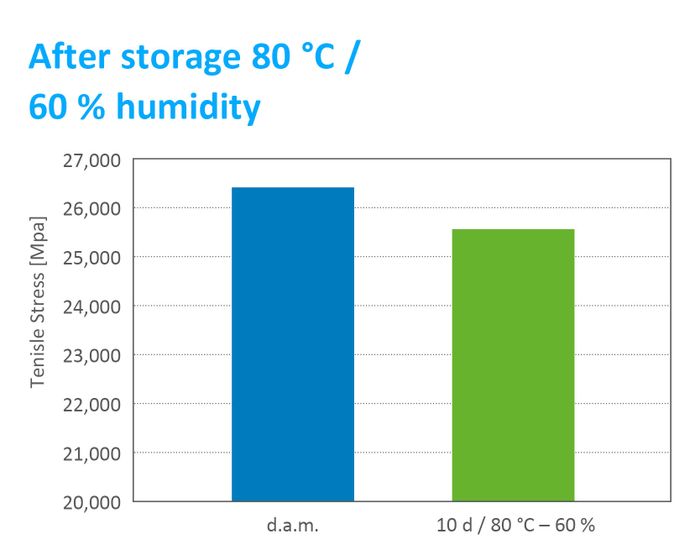

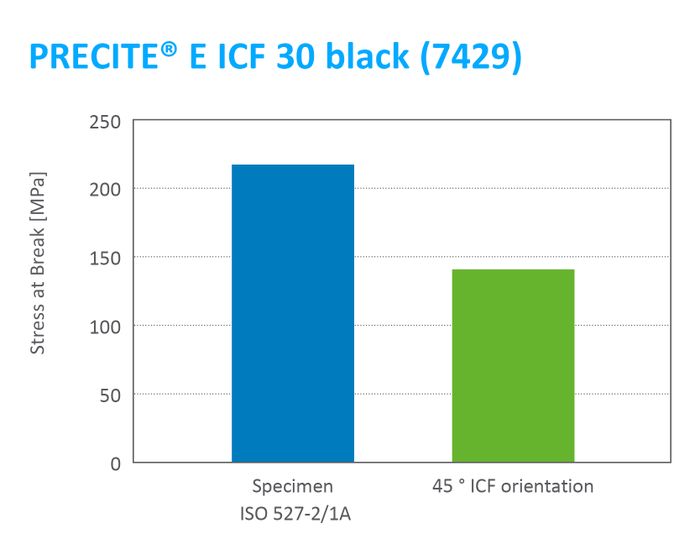

PRECITE® E shows unique performance combined with our affordable carbon fibre reinforcement ICF. The 30% reinforced PRECITE® E ICF 30 black (7429) has a modulus of 25 MPa. Even after 240 days at 80°C / 60% humidity the mechanical performance is still the same. Moreover we measured the modulus at 45°C orientation shows even 15 GPa stifnessand 140 MPa strength.

Particularly notable is the good bonding of our ICF with our polyester compounds. Both PBT and BET show excellent performance even with 45° and 90° oriented carbon fibers. As can be seen here in the example of PRECITE® E ICF 30 black (7429).

This property is particularly important for technically highly demanding applications. Components, such as the carrying arm which are subjected to high loads in all directions in the event of a crash, can be easily accompanied by PRECITE® E ICF 30 black (7429).

Image dimensions not found

Change image or reupload it

Applications

Automotive interieur (lamellas, structural parts)

Automotive exterieur (wiperarms, mirror housing)

Automotive UTH (struktural parts, electrical components)

Appliances (ovenhandle, visible parts)

In general tribological application like gears

In general parts where good surface is required

Food applications

Disclaimer: All specifications and information given on this website are based on our current knowledge and experience. A legally binding promise of certain characteristics or suitability for a concrete individual case cannot be derived from this information. The information supplied here is not intended to release processors and users from the responsibility of carrying out their own tests and inspections in each concrete individual case. AKRO®, AKROMID®, AKROLEN®, AKROLOY®, AKROTEK®, ICX®, PRECITE® and DIA(hr)LOG® are registered trademarks of AKRO-PLASTIC GmbH.